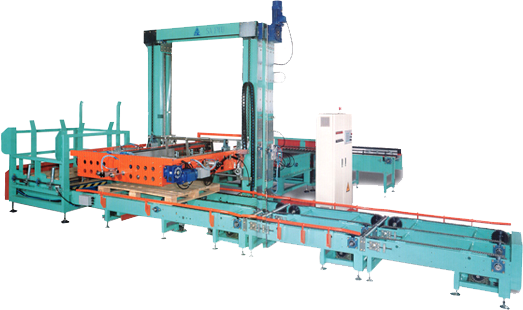

Low Level Palletisers Machine

Machine's Features

- Designed for stacking various types of carton, box and plastic basket.

- Employs man-machine interfacing English screen, providing display for trouble causes, self-diagnosis and trouble positions.

- Carton stacking quantity and layers can be set on the control panel

- Extensible height frame for elevation of upper tape head mechanism with a range of 400mm, adjusted by crank handle.

- Touch-sensing screen provides memory capability for memorizing the slacking programs for saving time of change.

- All moving parts are equipped with grease nipples for convenient lubrication and maintenance.

- Low bed construction allows for convenient repairing and shooting trouble.

- Applicable Products : Well packed products in carton, box and plastic basket.

Specification & Model

- Power Source:

- 220V-440V / 50Hz-60HZ

- Air Pressure:

- 5-6.0 kg/cm

- Air Flow Consumption:

- 200L / min

- Machine Dimensions:

- L6l25mm x W5139mm x H2995mm

- Machine Weight:

- 3200kg

- Processing Capacity:

- 30-40 cartons / min

- Operation Control:

- English screen display system

- Packaging Material:

- Plastic Pallet, Wooden Pallet ond Paper Pallet

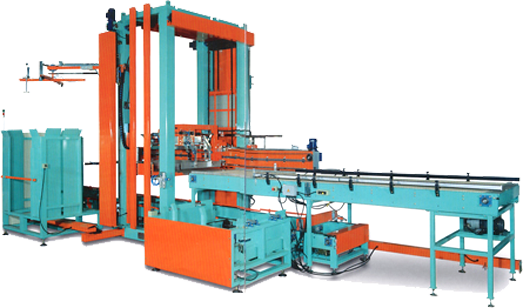

Low Level Empty Bottle Depalletisers Machine

Features

- Man-Machine interface control panel both in English/Chinese version provides automatic display for error message and position guide for operation.

- Automatic paper take-out combined with automatic stacking to eliminate troublesome take-out by manual operation. This also provides convenience for moving by forklift.

- Empty bottle pallets are stacked automatically.

- Empty bottles pallets operate automatically with a frequency inverter, assuring smooth motion without damaging on empty bottles.

- Empty bottle pallets are collected and stacked automatically and suitable for various shapes of bottles and cans.

- All moving parts are equipped with grease nipples for convenient lubrication and maintenance.

- Low bed construction allows for convenient maintenance.

- Applicable Products: PE bottle, PP bottle, PET bottle and Tin plate bottle.

Specification

- Power Source:

- 220V-440V/ 50HZ-60HZ

- Air Pressure:

- 5-6.0 kg/cm'

- Power Consumption:

- 10 lew

- Air Flow Consumption:

- lOOOL/min

- Machine Dimensions:

- LI 2081 mm x W8740mm x

- Machine Weight:

- 4200kg

- Processing Capacity:

- 1 -5 Layer / min

- Operation Control:

- English screen display system

- Packaging Material:

- Can, PE, PET, Glass and Bottle

For more options on different models please Contact Us!

Privacy Policy | Copyright 2018 © OGP. All Right Reserved | Site Designed by & Developed by Pixellence Web Solutions