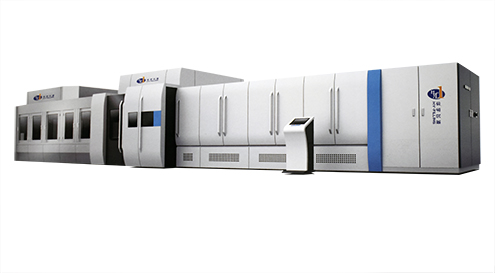

Blowing-Filling-Capping Combi Machine

The blowing machine heats PET performs first and then stretch blow mold with the compressed air. With the development of beverage production line speed, fully automatic rotary blowing machine becomes the main trend, which is widely used by large and medium-sized beverage plants. Blowing machine consists of preform sorter, heating machine, rotary blow molding host, and electrical control systems. With the high productivity and high efficiency, rotary blow molding machine becomes the first choice of the middle, high speed production line, while the linear blow molding machine is chosen in the middle and low-speed production line.

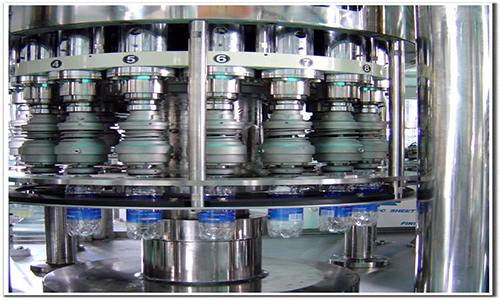

Filling part:

- We introduce into Germany technology for the filling machine, and design & manufacture by ourselves with isobar filling principle.

- Filling valve adopts constant pressure mechanism valve, filling fast and high accuracy of filling liquid level. It is adopted double guide rod structure.

- The main drive adopts gear drive, with high efficiency, low noise, long life, easy maintenance, sufficient lubrication, grease can lubricate centralizing automatically, adopts transducer to the speed of main motor to control, the machine adopts step-less frequency conversion timing. The material for the whole platform and frame is carbon steel with stainless steel outside..

- Applicable for wrapping various products, such as tin plate can, PVC bottle, PET bottle, glass bottle and aluminium folil box.

- The machine is automatically controlled by PLC, fault on line display, like bottle block, cap shortage etc.

- The key parts and electric elements of the machine are adopt import products.

Capping parts:

- The capping rotates through reduction box drive rotational wheel, which make the cap leave the hopper with the function of centrifugal force. There is a separation device for right cap and reverse cap at the entrance, when the reverse cap passes, the cap automatically fall into and return to pipeline, and blow the reverse cap automatically to hopper through wind power.

- Only right cap could enter into skids smoothly, the volume of cap inside of hopper will be automatic inspected by electric switch to control cap conveyor, and that ensures best effect of cap down.

- When the right cap enters into the slide way, it could smoothly enter into cap feed plate, to prevent accidents, there is an anti reverse cap drive plate device to match with slide way, to ensure that the access to the cap feed plate is correct.

- The slide way is also equipped with a pair of photoelectric switch, when testing no cap, then an immediate halt to the host. In order to effectively remove non-anti-theft ring bad caps and cleanup additional caps in hopper, there is an active exit in front of the hopper exit can meet this function.

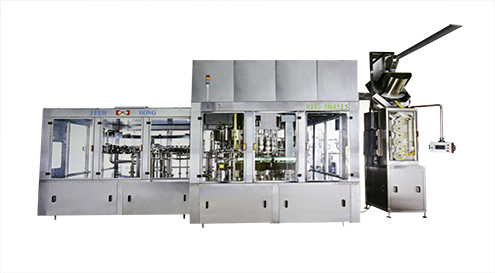

Automatic Bottle Rinsing/Filling/Capping Machine

The Automatic Bottle Rinsing/Filling/Capping Machine is

covered with tempered glass and stainless steel frame

& sliding door to keep clean.

Air filter device (HEPA) is optional which can be installed on top of the machine.

The Automatic Bottle Rinsing/Filling/Capping Machine adopts neck handling type bottle feeding design and there is no need of in-feed screw for diverse bottle-size.

Rinsing

- This kind of Bottle Rinsing Machine is to conduct the draining step immediately after the bottle rinsing.

- Its spraying route is simpler.

- But in comparison with the bottle rinsing machine that has the same rinser quantity, its spraying and draining duration will be kind of longer than the Two Section Rinsing Machine.

- The suitable rinsing agent for this Single-Section Bottle Rinsing Machine includes ozone water, low concentrated H2O2, low concentrated chlorine water because the residual of these rinsing agents will not affect the products too much.

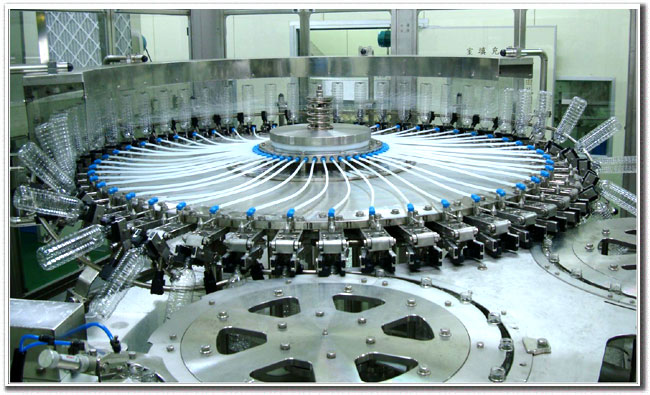

Filling

- For this type of Filler for PET bottles, we design it as Bottle Neck Hanging Type which is simple structure and not easy to be damaged.

- Under the bottle hanging star wheel, the bottle supporting star wheel is made of stainless steel which is firm and durable.

- The bottle hanging device of Filler is placed under the Filling Valves, so the bottle hanging elevating motion won’t pollute the filling valve. Our Filling System discharges the air inside the bottles to the Gas-Liquid Separation Tank which can prevent the air inside the bottle polluting the filling products inside the Filling Bowl.

- The control system of Filler is open which can provide the mixing system with the connection control. This surely ensures the product safety.

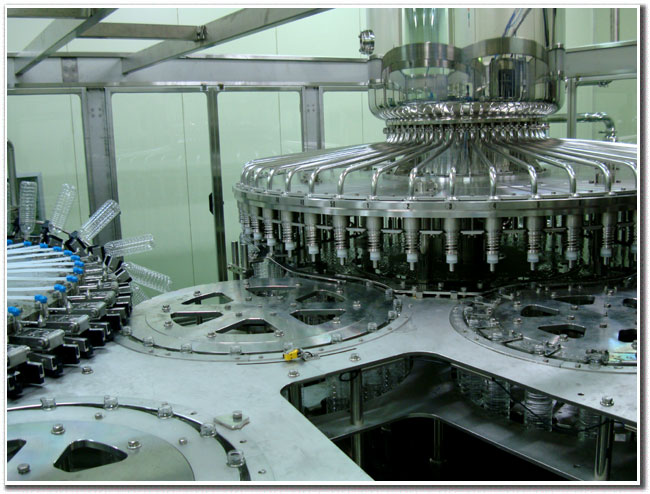

Capping

- The Capper Machine for Plastic Screw Cap is very commonly adopted for milk, juice, water, tea, and sports drinks industry

- Mostly Capper Machines for plastic screw cap are applied to plastic bottles, but some of them are applied to glass bottles

- What’s more, there are some so-called combination caps which only need to be pressed without turning.

- Due to the boost in price of plastic material recently, many companies start adopting shorter cap to reduce the weight of cap and bottle top in order to save cost, gain competition, and also contribute to environmental protection.

Edible Oil Machine

Features

- Index-6 offers multiblocs from the Pragmatic series with weight dosing. The machines are ideal for filling of liquid, edible oils including vegetable oil, olive oil and many others (sesame, flax, walnut, corn, grape seed, etc.).

- Index-6 offers multiblocs from the Pragmatic series with weight dosing.

- The machines are ideal for filling of liquid, edible oils including vegetable oil, olive oil and many others (sesame, flax, walnut, corn, grape seed, etc.) all these oils have a specific viscosity range that determines the chosen filling valves for the machinery.

- When applying weight dosing, utilizing highly precise and reliable load cells, we can guarantee excellent accuracy and smooth laminar gravitational flow of the product, keeping its structure intact.

- The use of our patented filling valve combined with controlled multi-degree valve opening and closing system allows us to achieve high filling speed on top of all the above features.

For more options on different models please Contact Us!

Privacy Policy | Copyright 2018 © OGP. All Right Reserved | Site Designed by & Developed by Pixellence Web Solutions